Expertise

Problem Scoping & Strategic Analysis

Unlock clarity and alignment to solve the right problems at the right level.

Decoding complexity to guide your toughest decisions

At the heart of every successful transformation lies a clear understanding of the system of interest and the problem it faces. At Systemic Intelligence, we specialize in diagnosing complex industrial situations through a systemic lens — Building crystal clear and collaborative representations of your industrial systems that integrate its business & technical environment, unvaluable to identify the internal & external root causes and find relevant solutions to complex industrial issues. Whether you’re launching a new initiative or tackling persistent inefficiencies, our approach results in pragmatic, activable recommendations and helps structure the path forward for your teams.

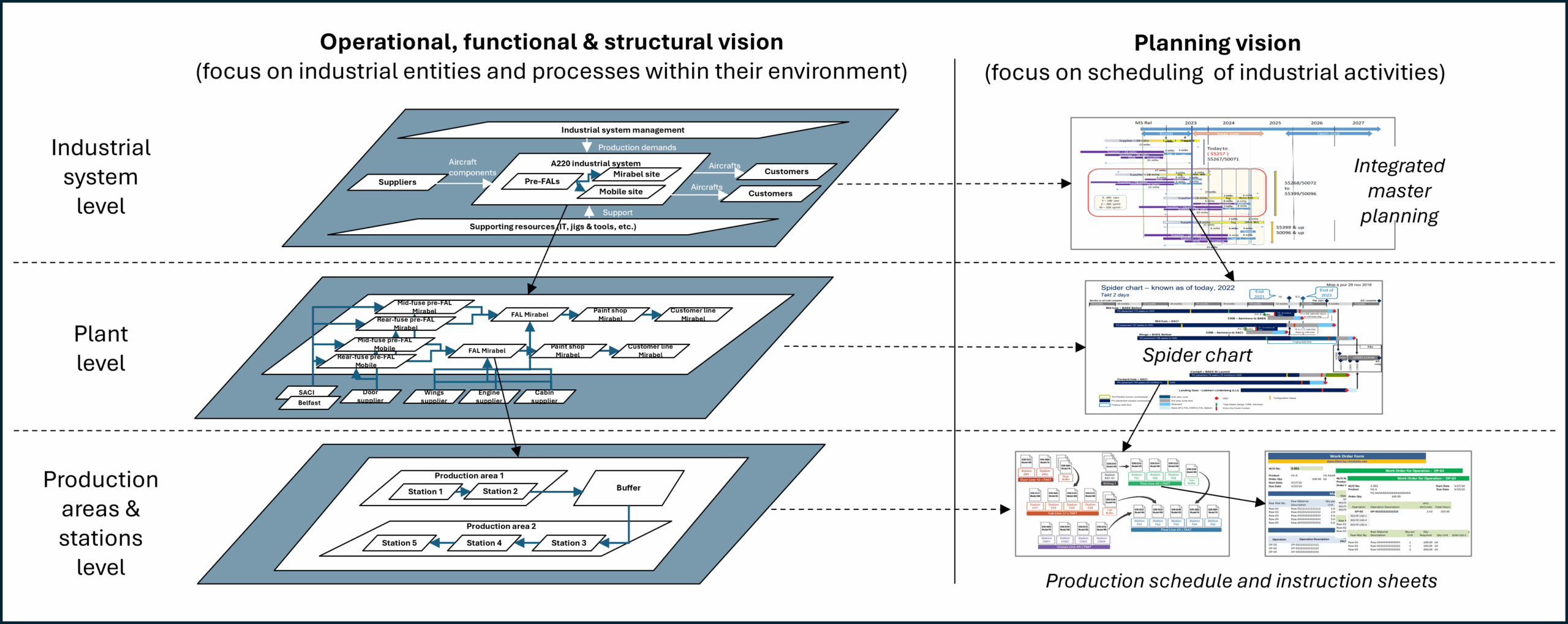

Our systemic analysis framework for industrial systems

- System Mapping

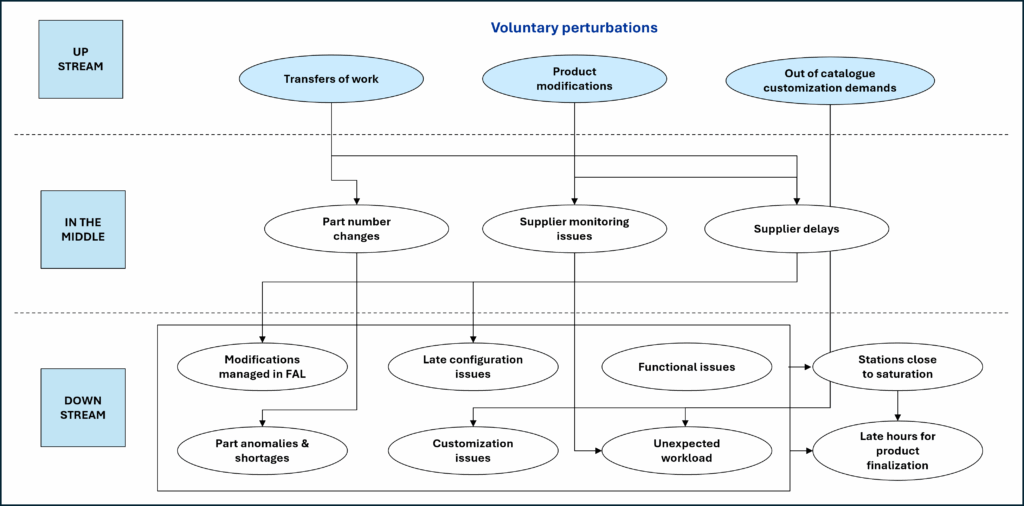

Visualize and model interactions between processes, equipment, and stakeholders—revealing hidden feedback loops and leverage points. - Impact Forecasting

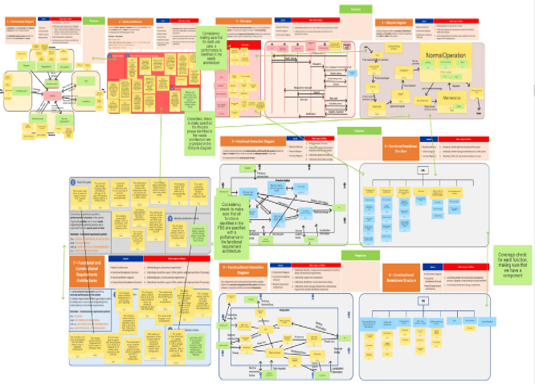

Run “what-if” scenarios to predict how changes ripple through the entire system before committing to action. - Collaborative Sense-Making Workshops

Facilitate hands-on sessions with your teams to co-create and validate the system description, ensuring buy-in and shared understanding.

- Scope Boundary Definition

By clearly mapping inputs, outputs, and interfaces, we define precise initiative boundaries. This structured approach prevents scope creep and ensures all teams remain aligned on deliverables. - In-Depth System Diagnostics

We engage directly with key stakeholders through interviews and collaborative workshops to deeply understand how your industrial systems operate. This human-centered approach enables us to construct unified system representations—such as environment and process views—that reveal how the systemic components of an industrial system interact. These visual tools not only aid in identifying issues and constraints but also serve as a basis for mapping pain points and developing practical, targeted solutions. - Critical Parameter Identification

By pinpointing key variables—through sensitivity checks and performance thresholds—we isolate the core factors that drive throughput, quality and cost.

- Workshops (on-site or remote)

We facilitate structured sessions to align on goals, map processes, or prioritize initiatives—drawing on our experience in systems thinking, facilitation, and industrial operations. - One-on-One Interviews

We conduct targeted interviews to surface individual insights, pain points, and tacit knowledge—leveraging our technical background to interpret context and connect dots across roles. - Gemba Walks / On-Site Observations

By observing operations directly, we validate stakeholder input and identify unspoken constraints—thanks to our hands-on understanding of industrial environments and lean diagnostic methods. - Remote Collaboration Tools

We are experts in the use digital whiteboards and collaborative platforms to engage distributed teams, ensuring participation and alignment through clear visuals and structured guidance. - Co-creation of Process Maps or System Diagrams

Together with stakeholders, we build unified representations—such as value stream maps or system schematics—using our ability to synthesize complex input into actionable visual models.

Consulting

Strategic and operational consulting to diagnose, plan and execute high-impact industrial projects.

Training & Coaching

Customized training programs, on-site or virtual, to build your team’s capabilities in systems thinking, industrial system modeling and change management.

Systemic Digital Twin Development

Development and deployment of digital twins that mirror your industrial processes for monitoring, simulation and optimization.