Expertise

Modeling and simulation of complex industrial systems

Support your decision making with quantified indicators, relying on advanced system simulations and data analyses.

Modeling and simulation as a key to keep complexity under control

We bring modeling and simulation to the core of every project that requires it —using it not as a simple accessory, but as a strategic capability. Backed by a robust platform designed specifically for complex industrial systems, we build digital models that mirror reality, simulate uncertainty, and reveal the true impact of design and operational choices. This allows us to explore a large array of scenarios, test assumptions, and deliver resilient, high-performance solutions with confidence.

- Multi-perspective integration

We develop representations that reflect the full complexity of industrial systems by integrating viewpoints from engineering, operations, logistics, and strategy. This ensures all stakeholders are aligned around a common, structured understanding of the industrial system of interest. - Holistic and iterative process

Our approach begins with a high-level view of the entire industrial system and progressively deepens, refining detail where needed to reflect critical industrial mechanisms. This flexible, step-by-step process ensures models remain relevant, scalable, and focused on the issues that matter most. - Legitimacy and broad applicability

The models we build are not just the show! They are credible, structured references that support strategic planning, design evaluation, performance analysis, and operational decisions. Their consistency and traceability make them legitimate assets throughout the industrial system’s lifecycle.

- High-Fidelity Simulation Engines

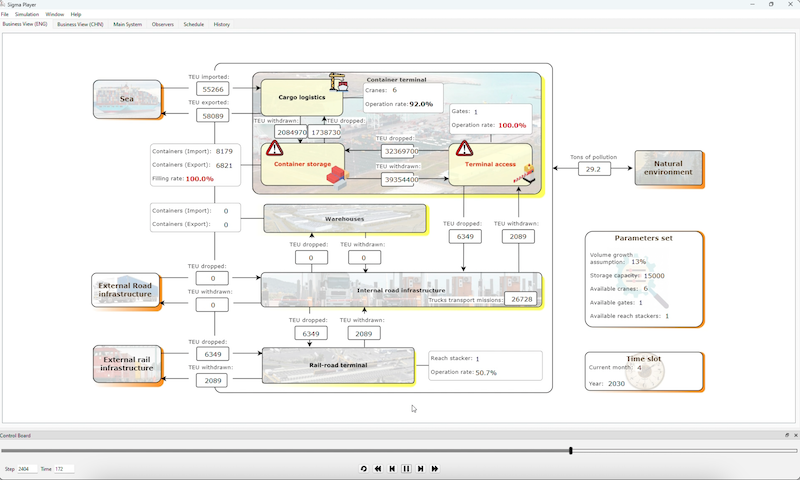

Leveraging best-in-class tools (e.g., discrete-event platforms), we create “digital twins” of your processes at the right level of granularity—capturing variability, resource constraints, and dynamic interactions. - Iterative Validation through Metaphoric Models

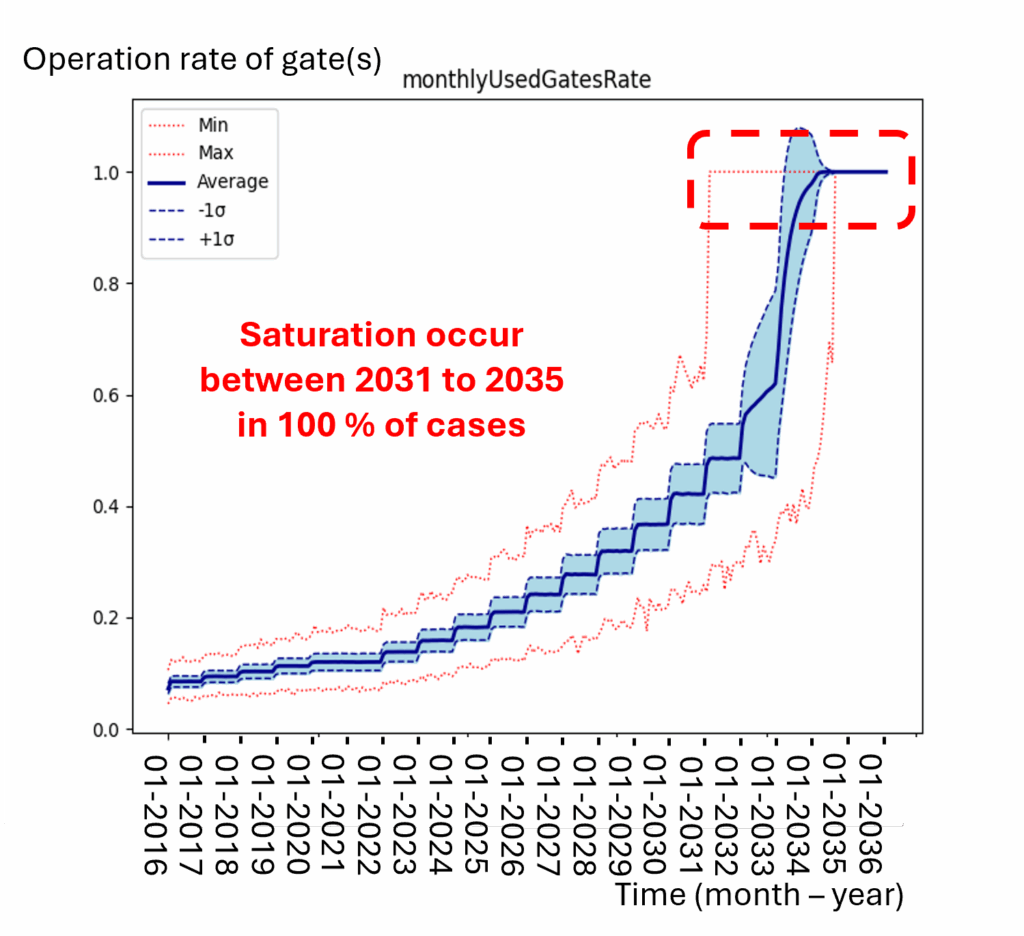

We build and test simplified, metaphorical short models that isolate specific industrial mechanisms—making it possible to validate assumptions, explain system behaviors, and confirm the influence of key variables on performance indicators in close dialogue with your industrial teams. - Scenario Exploration & Comparative Analysis

Rather than optimizing a single configuration, we define and simulate a variety of plausible system architectures and operational setups. Each scenario is treated as an experiment, allowing decision-makers to compare structural trade-offs and performance outcomes with clarity and confidence.

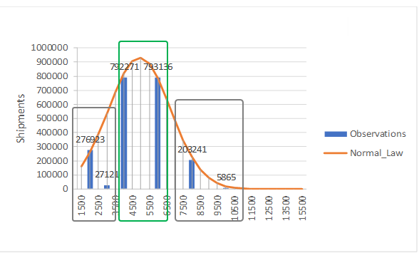

- Raw Data Structuring & Behavioral Abstraction

We collect, clean, and normalize data from heterogeneous sources (PLCs, historians, MES, IoT, etc.) to build a coherent, structured dataset. We then abstract these signals into behavioral variables, often estimating stochastic distributions and patterns that feed into our simulation and analysis pipelines. - KPI Derivation through Simulation-Enhanced Data Flows

We couple cleaned data streams with simulation models to derive dynamic KPIs tailored to operational priorities. These indicators support deviation detection, alerting, and performance measurement across scenarios and configurations. - User-Specific Dashboards & Analytical Views

We design adaptive dashboards that serve the right insights to the right users. Whether it’s a real-time alerting interface for operators, a performance cockpit for managers, or a drill-down analytics tool for data teams, each view is tailored to its audience—maximizing relevance and decision impact.

Consulting

Strategic and operational consulting to diagnose, plan and execute high-impact industrial projects.

Training & Coaching

Customized training programs, on-site or virtual, to build your team’s capabilities in systems thinking, industrial system modeling and change management.

Systemic Digital Twin Development

Development and deployment of digital twins that mirror your industrial processes for monitoring, simulation and optimization.