Systemic Digital Twins

Systemic Digital Twins enable

strategic and operational decision-making

for complex industrial infrastructures

Digital twins leverage behavioral and holistic representations of a system to assess in a realistic way its key performance indicators

Not the usual digital twins

Systemic Digital Twin is an innovative technology that transcends traditional digital twins approaches by enabling you to build models of complex systems that integrate a very large variety of interconnected and interdependent, heterogeneous internal and external components and take into account space & time hazards that often characterize such systems.

Systemic Digital Twins enable rich simulation experiences, through a vast variety of use cases. WorldLab™-based systemic digital twins are fully fledged enterprise solutions that support critical decision-making processes in complex industrial contexts such as infrastructure design, business or process transformation and strategic or tactical planning.

Business processes

in a single view

Systemic Digital Twins help business users to simulate their business processes. In a single view, they can both simulate their processes and see how their key business metrics evolve over time.

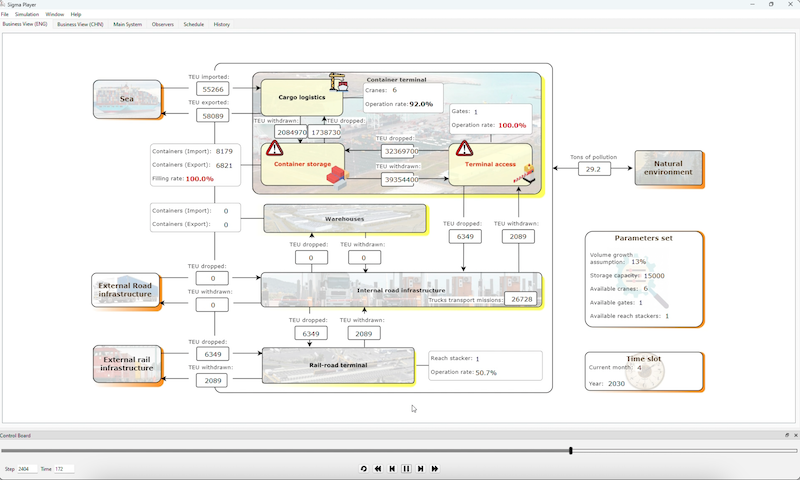

A major industrial harbor

Digital simulation of logistics flows within a large seaport to identify and secure industrial investments to adapt the port to an evolution of its logistic traffic.

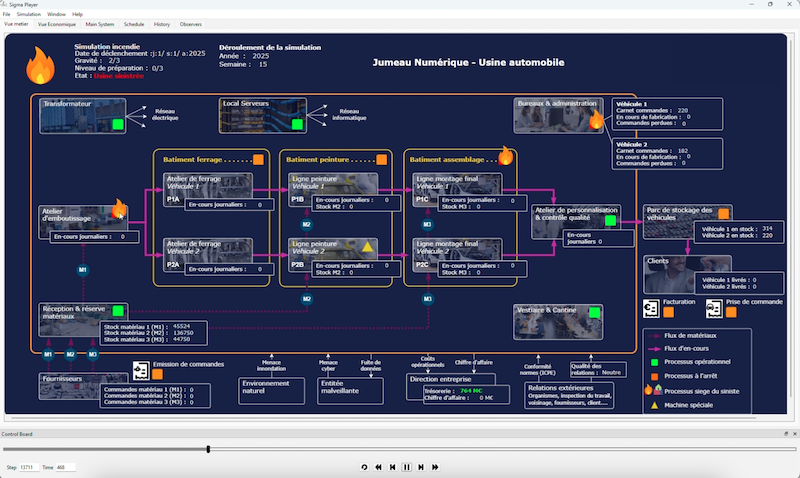

A car manufacturer

Systemic digital twin allowing the simulation of industrial risks (fire, flooding, cyber-attacks, etc.) in an automobile factory with the aim of analyzing the industrial & financial impacts in the event of a disaster.

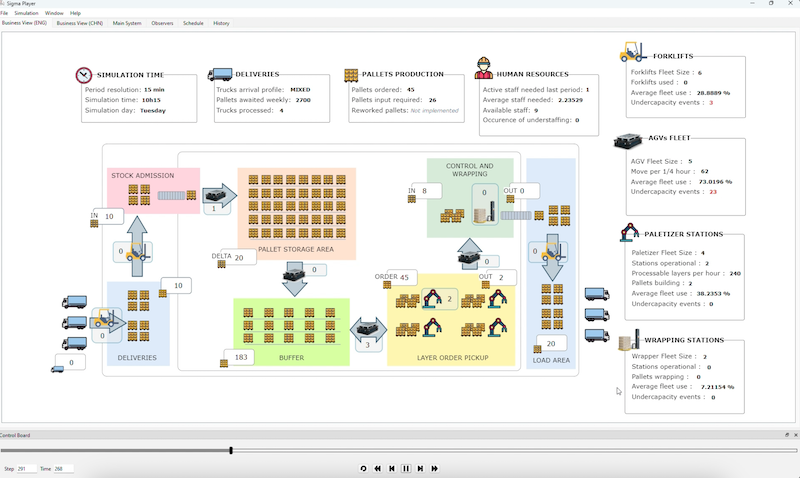

An industrial warehouse

Systemic digital twin to simulate the optimized sizing of an automated warehouse in order to optimize its operational productivity.

Key Features

WorldLab™ helps model specialists designing system models, integrating simulation data, and then creating, deploying, and using a systemic digital twin either on their local machine or via a web interface.

Heterogeneity

Systemic Digital Twins can be used to integrate technical functions, maintenance policies, societal behaviors, financial market evolutions, regulatory strategies, meteorologic conditions, etc., into a single unique systemic model, allowing to analyze a “real virtual twin” of an industrial system from all these various perspectives.

Concurrency & time

Systemic Digital Twins allow to manage concurrent industrial activities and express explicit durations for the activities that are performed by the system of interest. The discrete event paradigm on which we rely allows to limit the amount of computing resources, even when performing multiple Monte-Carlo simulations.

Hazards

Each variable specified in the Σ™ specification language can be tied to a generic or custom probability distribution. This allows to capture random quantities & delays through stochastic modelling and compute tactical and strategic indicators that takes into account the randomness that occurs in the real industrial environment.

Data abstraction

Input data for simulations are managed through abstraction mechanisms that capture significative trends and skip details when they are not necessary. This makes system models easier to design and more versatile. It also allows to maintain a good level of performance even when dealing with very complex simulations.

Facilitated design and maintainability

A Systemic Digital Twin is automatically generated from a high-level Σ™ specification. This makes maintenance for complex models and collaborative work much easier than with traditional approaches based on drag & drop of building blocks within an user interface.

Fast prototyping for agility

Our technology allows to quickly develop, typically within a few days or weeks, a first usable version of a Systemic Digital twin which can be used to iterate quiclkly and often with stakeholders through the faithful restitution in the business interfaces of the end-users. This allows to come up with a systemic digital twin fully aligned with the business user needs.

Scenarios evaluation & prioritization

WorldLab™ features mechanisms to develop scripted simulation experiments. This allows the end-users to easily evaluate and shortlist industrial options, such as infrastructure configurations, business transformation strategies, etc., through exploration and multi-criteria optimization.

Simulation indicators

System models may contain thousands of variables. However, a few fraction of them are actually needed to make decisions. WorldLab™ allows you to define indicators at model level, from which you can get statistical information about specific variables. Indicators can be used to close the loop in optimization virtual experiments, or be exported for “live” dash-boarding purpose.

Methodology

Our Systemic Digital Twin technology has been developed in consistency with CESAM, an industry-proven methodological approach for the modeling of complex systems and organizations. On this basis, we propose an end-to-end modeling approach covering the internal and external components as well as relevant techniques to manage systemic data.

Get your copy of our white paper: Manage the Systemic Digital Twin of an industrial Enterprise with WorldLab™ and Σ™

Using a systemic digital twin consists in creating & simulating evolution scenarios for an industrial system, executing the corresponding step-by-step and stochastic simulations and analyzing & optimizing their results, in order to manage continuous business improvements. The core deliverable of a systemic digital twin is indeed a set of key performance business indicators for various evolution scenarios, integrating volume & time hazards, of the considered industrial system, on which strategic or operational business decisions can be taken in the most relevant way. This paper intends to present – through an example – our approach to behavioral digital twins which integrate all core features that we just sketched here above.