Identify and act efficiently on the key levers of industrial performance — from reducing lead time to enhancing resilience and operational cost efficiency.

Reaching industrial performance target is often a difficult venture, as it can be strongly impacted by market volatility, technical constraints, and organizational inertia. We help our clients take control of this complexity with a systemic, model-driven approach. Our contributions typically focus on:

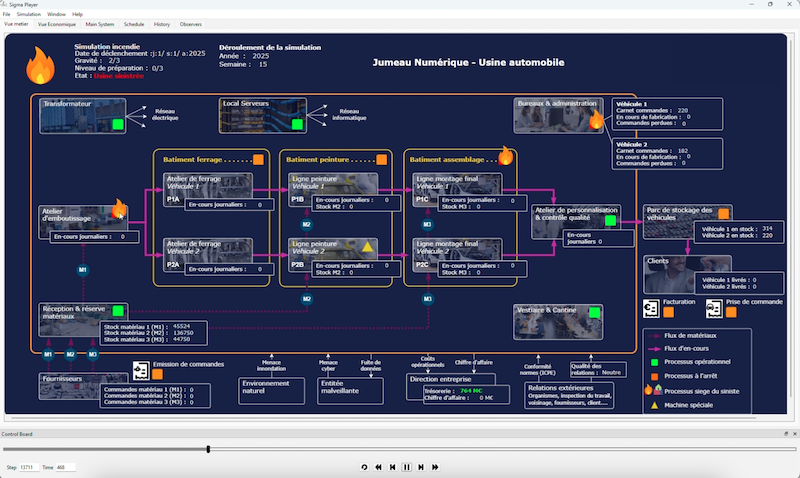

- Building a clear understanding of the dynamics of your industrial system by mapping how production flows and critical resources (tools, machines, operators, storage, etc.) interact under real-world conditions.

- Identifying key levers that influence throughput, variability, resource utilization, or cost-efficiency — across operations, supply chain, and governance.

- Testing scenarios and solutions through simulation to anticipate impacts, mitigate risks, and avoid costly surprises.

- Aligning teams around a shared understanding of challenges and options — bridging gaps between engineering, operations, and management.

- Enabling continuous improvement, by building digital assets (systemic industrial models, industrial configurations, industrial evolution scenarios, digital twins) that evolve with the industrial system and remain useful over time.

Our approach helps organizations move beyond surface-level fixes, enabling them to deliver measurable, lasting improvements in lead time, resilience, and cost control.

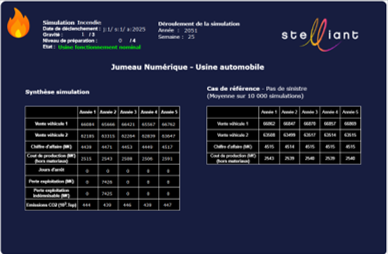

- Quantified the operational impacts of different disaster scenarios and plant industrial configurations.

- Identified optimal asset sizing and staffing strategies to maintain resilience while controlling costs.

- Demonstrated how prevention investments could effectively reduce risk exposure.

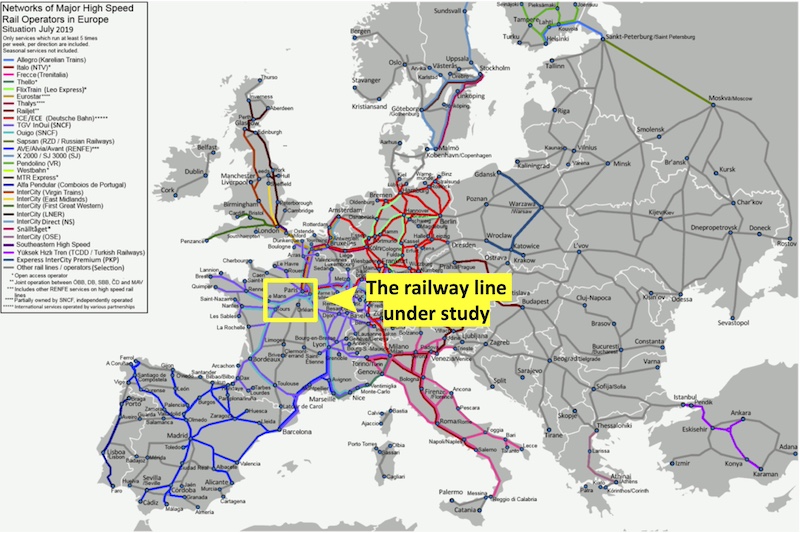

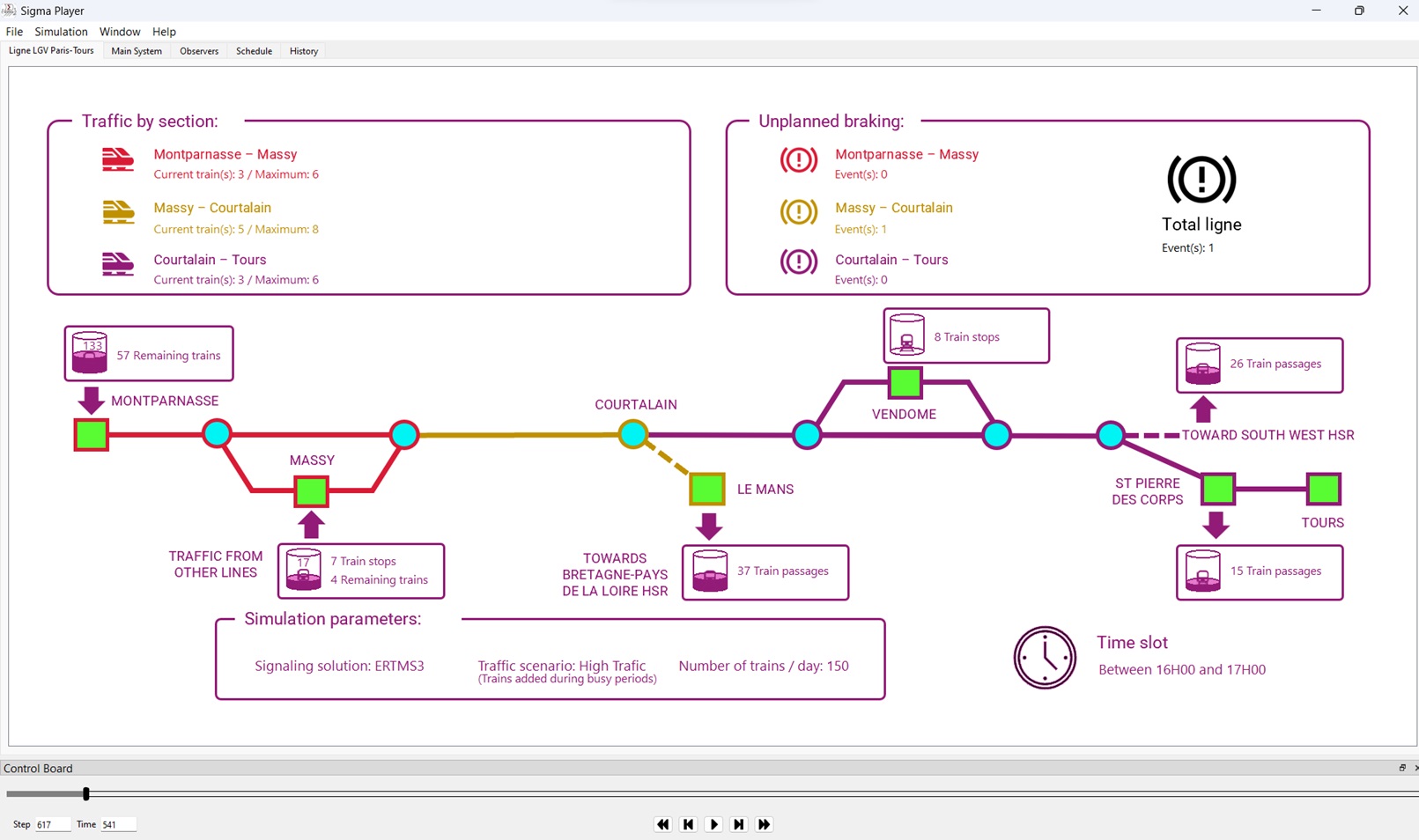

- Identification of the optimal trade-offs between capacity gains, safety performance, and cost for the new signaling configurations.

- Quantification of the impact of disruptions (maintenance, breakdowns, seasonal traffic) on the line performance under each scenario.

- Delivery of an operational analysis tool enabling the client to make well-informed architectural decisions.