Support critical transitions – new product introductions, production shifts, or reorganizations – through scenario-based planning and risk-informed decisions.

Industrial organizations are constantly exposed to deep transformations: introducing new products, adapting to market shifts, responding to new regulations, or modernizing legacy operations. These transitions are complex and risky: they involve critical decisions under uncertainty, often on tight timelines.

We help industrial leaders to structure these transitions and to secure performance by building a quantitative, systemic understanding of their operations — before critical decisions are made.

Our approach enables our clients to:

- Visualize and anticipate operational impacts of strategic decisions

- Evaluate risks and trade-offs across alternative scenarios

- Secure operational continuity and performance through well-informed choices

This is essential when an industrial organization must prepare for substantial changes in its industrial operations — whether launching a new product, reshaping its production flows, or adapting to a new business context.

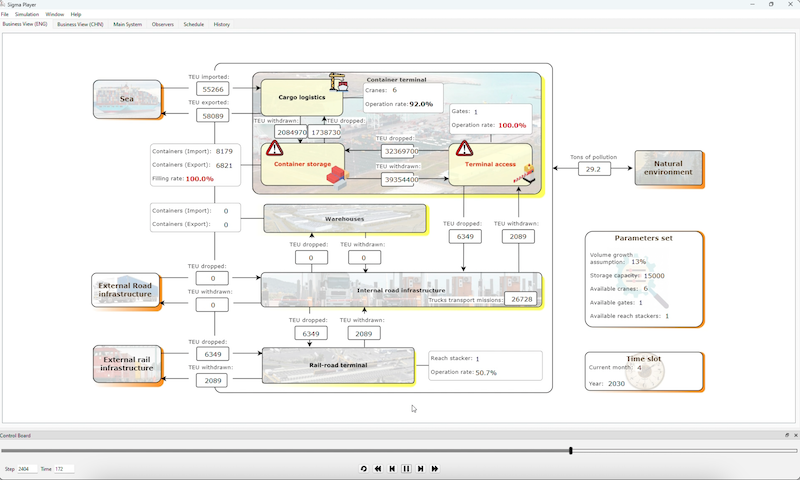

- A shared, cross-functional representation of the port’s logistics system, enabling effective collaboration between planning, operations, and infrastructure teams.

- Simulation reports, allowing:

- Identification of weak points in the current infrastructure under future traffic loads.

- Support in selecting the optimal sequencing and sizing of new logistics assets to minimize service disruption during the transition.

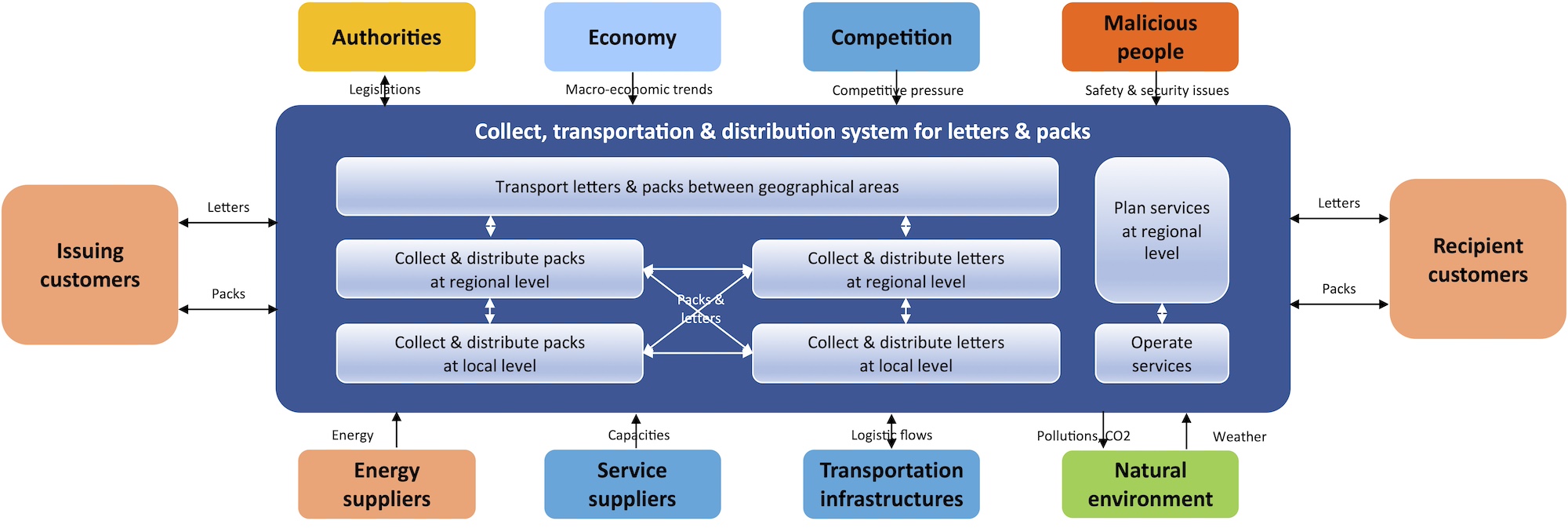

- A quantified, transversal view of the current logistics system.

- Simulation of structural evolutions and future load scenarios.

- Identification of key operational vulnerabilities and transformation levers.

- Evaluation of multiple network redesign options with respect to various key performance indicators.

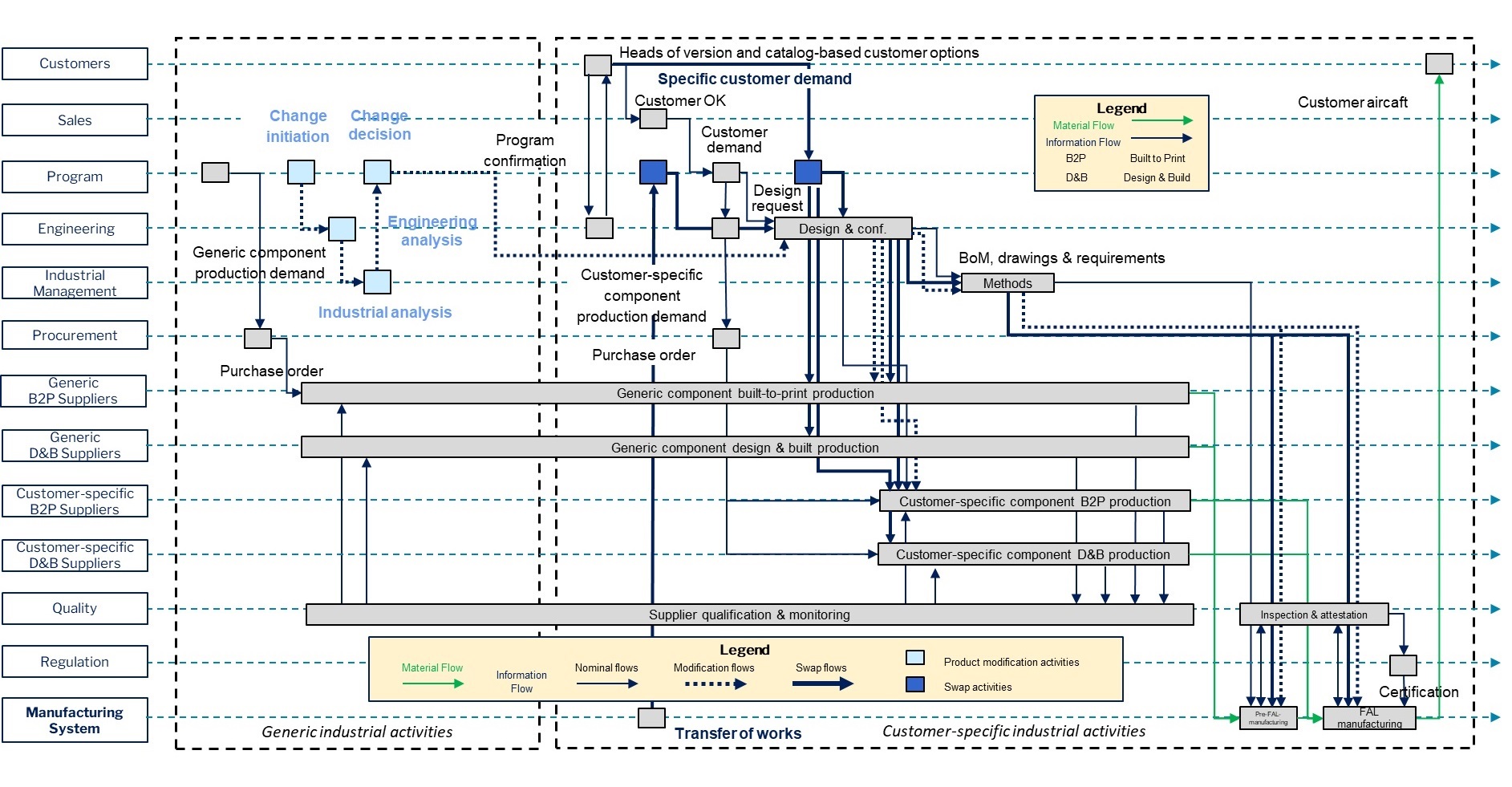

- A shared, dynamic model of the end-to-end industrial system: production, supply chain, governance, and market context

- Early identification of critical failure points in the context of ramp-up targets

- Actionable insights to improve agility, reduce lead times, and secure production throughput