Expertise

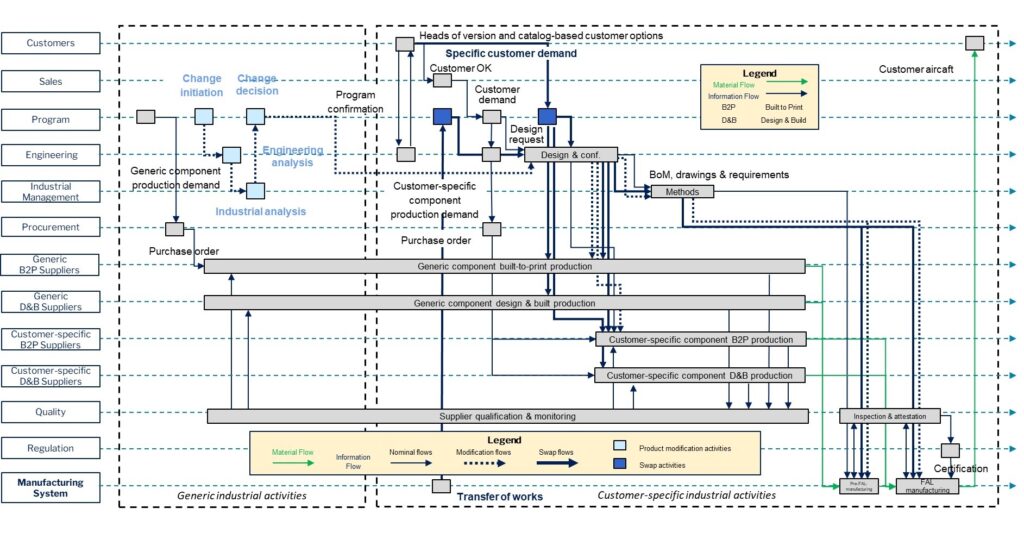

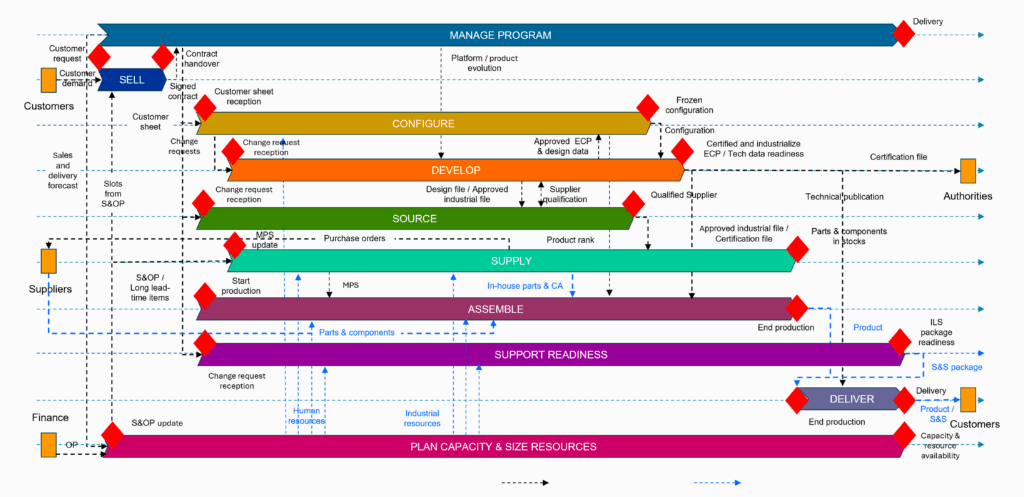

Industrial system design and change management

Get all the help you may need to build or transform complex industrial systems, able to face tomorrow’s challenges.

Turn business development intentions into activable plans to transform your industrial organization, or build a new one from the ground up

Industrial systems—regardless of their scale—are inherently complex. This complexity makes it difficult to anticipate how local decisions will affect the broader system, or to understand how uncertain operational conditions impact overall performance. Emerging constraints, including sustainability requirements, economic pressures from low-cost competition, and volatility in global supply chains and workforce availability, further increase this challenge. We help you navigate and master this complexity, reducing the risks associated with strategic industrial transformations.

- System-level thinking

We model your industrial infrastructure as a whole to ensure alignment between strategic intent, operational capabilities, and technical choices. - Architecture frameworks

We apply proven systems engineering methodologies to structure complex industrial environments across all lifecycle stages. - Traceability and coherence

We ensure that each architectural decision supports your objectives — whether operational efficiency, flexibility, sustainability, or cost control. - Adaptability by design

We help build systems that remain effective under uncertainty and can evolve with your business and technological landscape.

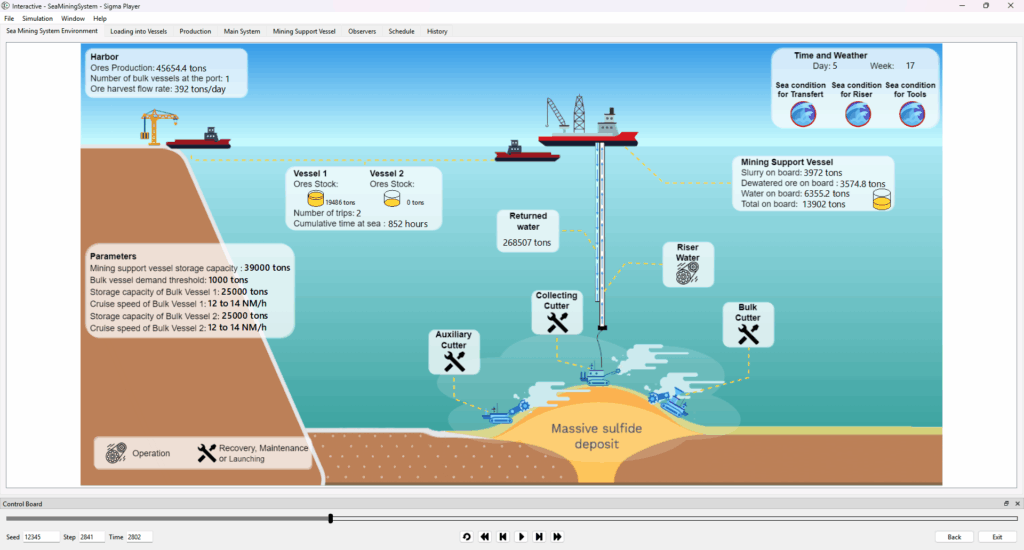

- Resource Allocation

We build detailed simulations of industrial processes that handle material transformation flows, integrating non-consumable resources such as equipment, workstations, and labor. These models enable precise sizing of your assets—eliminating both overcapacity and performance bottlenecks. - Real-World Calibration

Our teams integrate live production data to fine-tune simulation parameters—ensuring your virtual scenarios mirror on-the-ground performance within narrow error margins. - Scenario-Based Capacity Planning

Through the analysis of nominal and detrimental “what-if” scenarios (demand spikes, maintenance windows, supply disruptions, etc.), we deliver validated sizing recommendations that support the entire operational lifecycle of your industrial system, ensuring performance and resilience target are met.

- Shared Diagnosis

We perform rapid, systemic assessments—over a few weeks to a few months—to analyze your operations from end to end. Our goal: identifying the key inefficiencies and the deeper analyses required to address them. We formalize and share our findings in a collaborative half-day to 1-day workshop with stakeholders to ensure alignment and engagement. - Optimization Analysis

Going beyond surface-level symptoms, we investigate structural and operational inefficiencies to pinpoint their true root causes. Our recommendations combine targeted mitigation actions with practical solution concepts, which can include functional mock-ups or simulation-based proof-of-concepts to validate the proposed improvements. - Optimization Support

We accompany implementation efforts on the ground, mobilizing key actors and ensuring proposed changes are adopted effectively—translating insights into sustainable performance gains.

- Field-aligned transformation

We translate strategic objectives into operational reality, engaging teams across all levels to ensure relevance and ownership. - Systemic approach to change

We combine organizational analysis with system modeling to anticipate impacts, manage dependencies, and reduce resistance. - Stakeholder Involvement & Iterative Deployment

We organize practical involvement loops—co-designing change rollouts with key stakeholders and adjusting based on feedback from the field. This agile, participatory approach helps secure buy-in, surface practical concerns early, and anchor change sustainably. - Incremental transformation

We structure change into manageable phases, reducing disruption and enabling continuous improvement.

Consulting

Strategic and operational consulting to diagnose, plan and execute high-impact industrial projects.

Training & Coaching

Customized training programs, on-site or virtual, to build your team’s capabilities in systems thinking, industrial system modeling and change management.

Systemic Digital Twin Development

Development and deployment of digital twins that mirror your industrial processes for monitoring, simulation and optimization.