WorldLab for logistics

Transformation of logistics networks

➤ CHALLENGES

The logistics industry faces numerous challenges as it adapts to an increasingly complex and competitive global market.

The rise of e-commerce has reshaped the logistics landscape, creating new pressures to deliver goods faster and more efficiently. While this surge in demand presents opportunities, it also introduces problems related to capacity management. Warehousing, fleet management, and last-mile delivery systems often become bottlenecks, especially during peak periods. Companies that are unable to scale quickly and flexibly may struggle to keep up with competitors that have adopted more agile models.

Digital transformation in logistics presents both opportunities and challenges. The adoption of new technologies—such as automation, artificial intelligence, and data analytics—has the potential to revolutionize the industry.

In addition, many companies must adapt their infrastructure to the business changes that impact them, either by resizing them or optimizing them.

➤ SOLUTIONS

Addressing these challenges requires a holistic, systemic approach. Logistics companies must invest in digital tools that provide end-to-end visibility of their supply chains, enabling them to react swiftly to disruptions and optimize route planning and fleet management. Simulation tools can be valuable for testing different operational scenarios, allowing companies to foresee potential bottlenecks and inefficiencies before they impact operations. By tackling these challenges head-on and investing in the right solutions, logistics companies can stay competitive and continue to deliver value to customers in an increasingly demanding market.

➤ WorldLab™ for logistics

Whatever the systemic level of your concern : intralogistics, logistic node, medium-size logistic hub, large-scale logistic network, etc. WorldLab™ can help you finding optimum architectures & configurations for existing / new logistic infrastructures or logistic transformation projects, and facilitate your day-to-day / month-to-month decision making for the logistic systems that you operate.

Case Studies

Analyzing the transformation of the logistic activities of a maritime hub

The challenge

In the context of an expected, but still uncertain, strong forthcoming growth of its container traffic, a large French industrial seaport must secure a major investment plan dedicated to the construction of new logistic infrastructures to support that growth and assess the resilience of its current logistics facilities in order to minimize the impacts of its logistic transformation on these facilities which are managing the different traffic (i.e. ships, containers, trucks, railways and river barges) supported by the port.

Our approach

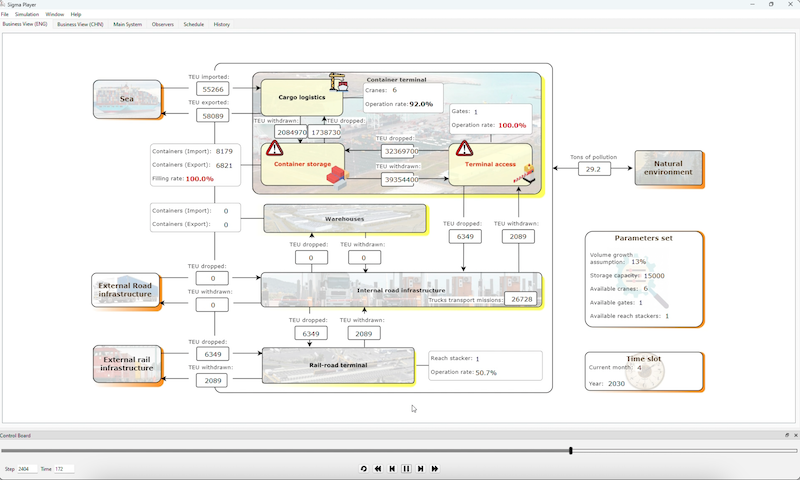

Our answer was based on the construction of a systemic digital twin of the transformation perimeter within the industrial port, relying on a realistic systemic model of this industrial system, including its environment, which allowed us to simulate it and evaluate the key performance indicators that are measuring the impacts of the transformation of the container traffic of the port on the logistic infrastructures that it manages.

The outcomes

FEATURES

Service features that were deployed in this case:

– Structural & behavioral modeling of an industrial port

– Analysis of operational data of an industrial port environment

Product features that were used in this case:

– Implementation of a systemic model in Σ™

– Connection with external data sources

– Step-by-step and stochastic simulation

– Scenario simulation and evaluation

ADVANTAGES

Container traffic trends were modeled and simulated in order to capture the evolution over time of the main logistic inputs of the industrial port under study.

All business & industrial hazards and disruptions (e.g. variations & changes in operating modes, seasonality of operations, weather conditions, traffic jams, lack of resources, etc.) that the industrial port must face were integrated in our model.

Systemic digital twin maintenance & evolution could be regularly achieved with a very low effort.

BENEFITS

Benefit #1: the very first benefit of our approach mentioned by our client was the construction of a shared global & transversal quantitative vision of the scope of interest in the industrial port which was lacking within the port teams.

Benefit #2: our approach made it possible to identify the main business impacts of the targeted logistic transformation on the port’s existing logistic infrastructures and made it possible to make the optimal design choices for the new logistic facilities to construct.

Facilitating decision making for the evolution

of a large logistic network

The challenge

Our client is a historic mail operator: it operates a large-scale mail distribution network together with the associated industrial infrastructure which manages the collection, transportation & delivery of letters & parcels at national level. However, the constant decline in postal traffic, combined with the explosion of parcels and cross-border exchanges, is calling into question the traditional mail sorting & distribution model.

Our client is therefore faced with a critical industrial challenge consisting of modernizing its industrial letter & parcel management industrial tool in the near future in order to ensure the sustainability of its activity, while guaranteeing optimal customer satisfaction.

Our approach

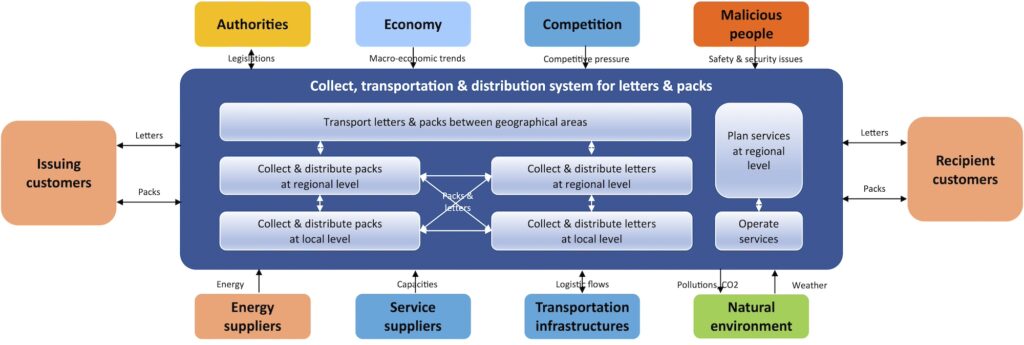

To meet the industrial challenge of our customer, we proposed to construct a systemic digital twin of the collect, transportation & distribution system for letters & packs, based on a realistic systemic model whose overall structure is presented here, which allowed us to simulate it and to evaluate & compare different coarse grain evolution scenarios for this system.

The outcomes

FEATURES

Service features that were deployed here:

– Structural and behavioral modeling and analysis of operational data of the system for collecting, transporting and distributing letters and packages

Product features that were used here:

– Implementation of a systemic model in Σ™

– Connection with internal operational data sources

– Step-by-step and stochastic simulation

– Scenario simulation and evaluation

ADVANTAGES

Customer behaviors and traffic trends were modeled and simulated in order to capture the evolution of letter and parcel traffic over time.

All commercial and industrial hazards and disruptions (e.g. breakdowns and maintenance periods of industrial distribution machines and transport devices, seasonality of traffic, lack of resources, etc.) presented by the considered collection, transport and distribution system for letters and packages, was modeled without any problem.

Systemic digital twin maintenance & evolution could be regularly achieved with a very low effort.

BENEFITS

Benefit #1: the very first benefit of our approach mentioned by our client was the construction of a shared global & transversal quantitative vision on the considered system of collection, transport and distribution of letters and parcels.

Benefit #2: our approach led to the evaluation of different scenarios for the evolution of our client’s system for collecting, transporting and distributing letters and packages and made it possible to make the optimal design choices for its transformation.