Case Studies

We provide a systemic digital twin solution for optimizing complex business operations: WorldLab™

Our WorldLab™ flagship solution makes it possible to cope with the evolution of complex industrial systems such as manufacturing systems, supply chains or industrial infrastructures

A completely new approach to managing complex industrial operations

Our goal is to help managers of complex industrial infrastructures to better globally optimize their operations by using systemic digital twins which are new-generation decision support tools based on systemic approaches. A typical problem that can be addressed in this way, for example, is to maximize business & industrial performance under the constraint of minimizing energy consumption & environmental footprint while optimizing societal benefits and taking operational hazards into consideration.

Optimizing industrial operations

Modern industries must optimize complex interdependent operational ecosystems, such as their supply chain, their logistics, their production systems, their distribution systems, their day-to-day customer operations, their maintenance systems, etc., taking into consideration complex economical, political, social, technological, legal & environmental constraints from a tactical and strategic perspective.

Optimization of industrial operations rely on operational, tactical & strategic challenges. Being able to take the right such decisions in complex environment is key.

Strategic industrial decisions

• What is the optimal global architecture for an industrial system?

• What is the optimal design for a new industrial facility?

• What is the industrial evolution scenario with less risks & costs?

• What is the best way to manage an industrial process?

• What is the optimal way to manage an industrial ramp-up?

• What is the optimal industrial maintenance strategy to follow?

• …

Operational & tactical industrial decisions

• How to optimize my industrial lead time during operations?

• How to minimize non quality during industrial operations?

• How to determine the root causes of an operational inefficiency?

• How to optimally reconfigure my industrial production?

• How to minimize energy & wastes during industrial operations?

• How to decrease the environmental footprint during industrial operations?

• …

Our unique systemic vision

Functional, functional, functional …

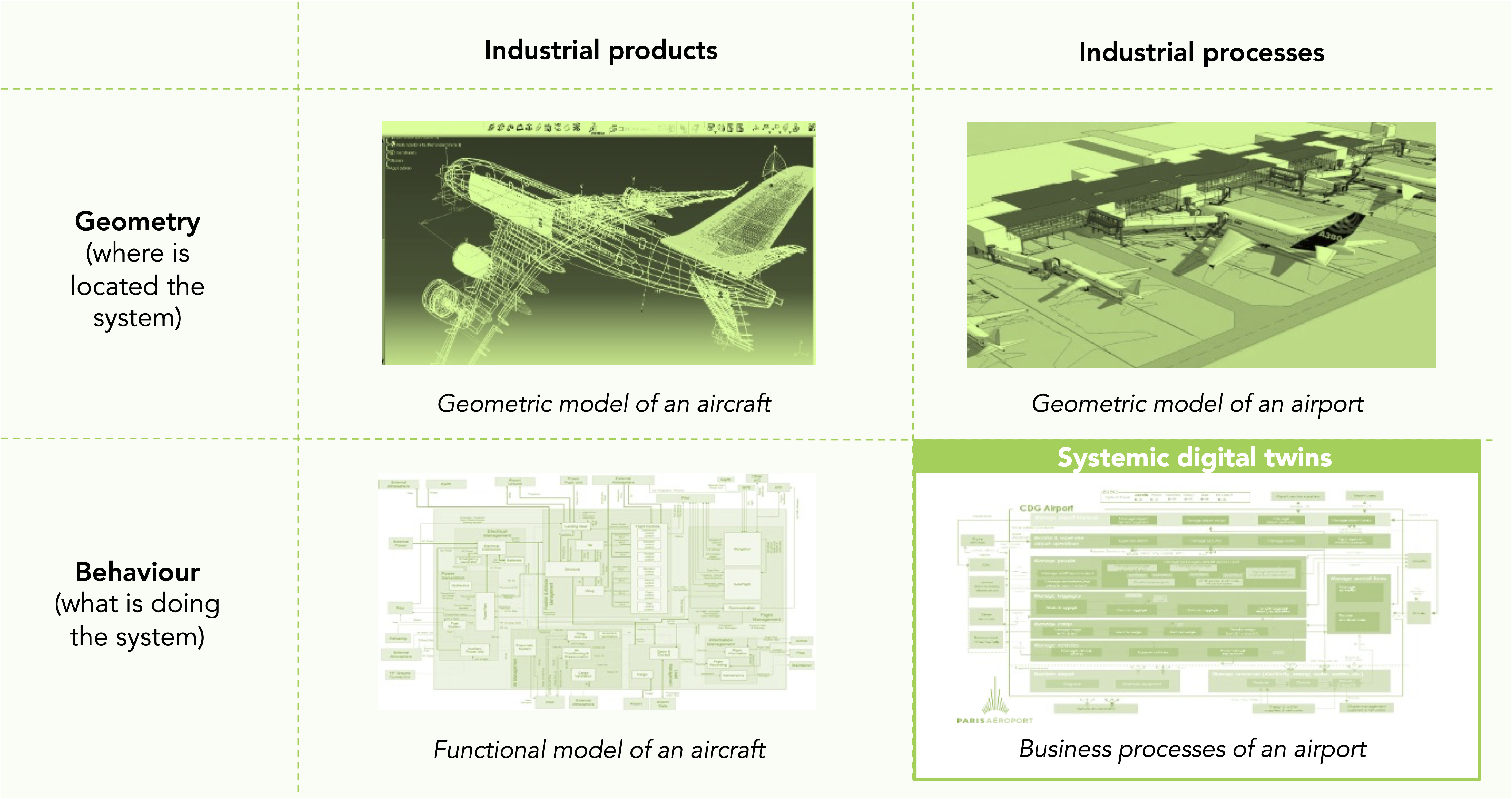

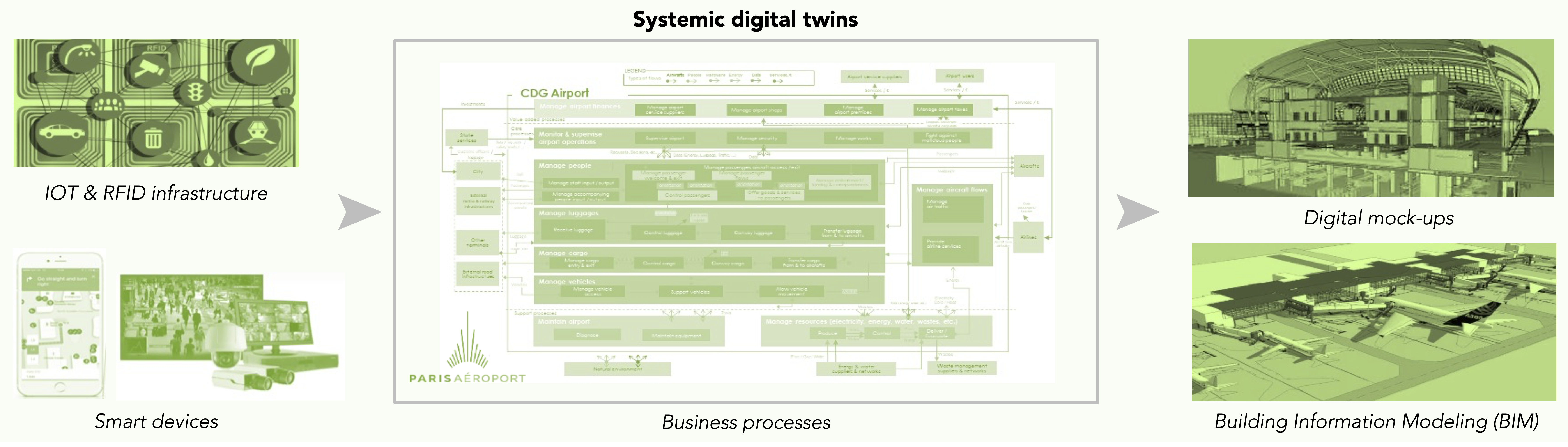

Our point of view relies on a functional paradigm focused on industrial processes. Systemic digital twins implement this vision by simulating & optimizing industrial processes associated with complex industrial systems based on a systemic vision, coupled with a stochastic modeling approach in order to take into account all the space & time hazards that characterize any industrial operation.

Current solutions on the market focus either on data-related infrastructures or on geometric representations. We believe that digital twins should use a functional point of view. They should indeed be able to model and simulate the behavior, i.e. the business processes, of an industrial system, starting from operational data and ending by enriching decision-making dashboards or digital models. This is why we are following an enterprise architecture approach which is one of our main differences from existing digital twin technology.

Our case studies

Our vision applied to concretely solve industrial challenges.