Manufacturing & Supply Chain

Manufacturing and supply chain industry overview

Manufacturing involves the management of the production process from raw materials & product components to the finished product, encompassing various stages such as assembly, integration and delivery.

Making decisions for the design, transformation, or tactical and strategic operational planning of manufacturing infrastructures is complicated due to the intricate nature of manufacturing systems. One must indeed navigate numerous internal components with diverse characteristics, managing a myriad of processes such as material procuring and transformation, assembling,& integration and delivery. Moreover, one shall also deal with a multitude of dynamic flows and constraints —often marked by high levels of uncertainty—originating from external factors.

This industrial complexity adds a layer of challenge to decision-making processes, requiring careful consideration of diverse elements both within and outside the manufacturing environment.

Whatever the systemic level of your concern: production floor, manufacturing plant, multi-site manufacturing systems or large-scale industrial network, etc., WorldLab™ can help you finding optimum configurations for existing / new infrastructures or industrial transformation projects and facilitate your day-to-day/month-to-month decision-making for the industrial systems that you operate.

Final Assembly Line ramp-up assessment

The challenge

A commercial aircraft manufacturer is preparing to increase the production in its final assembly line (FAL) in order to meet the market demand. However, its industrial facilities are at the limit of their capacity, and one needs to understand what to do in order to achieve a successful ramp-up consisting in doubling the current production rate in the short & medium term. Our customer asked us to analyze the current weaknesses of its industrial system and to propose relevant mitigation actions in order to optimally prepare it for the targeted industrial ramp-up.

Our approach

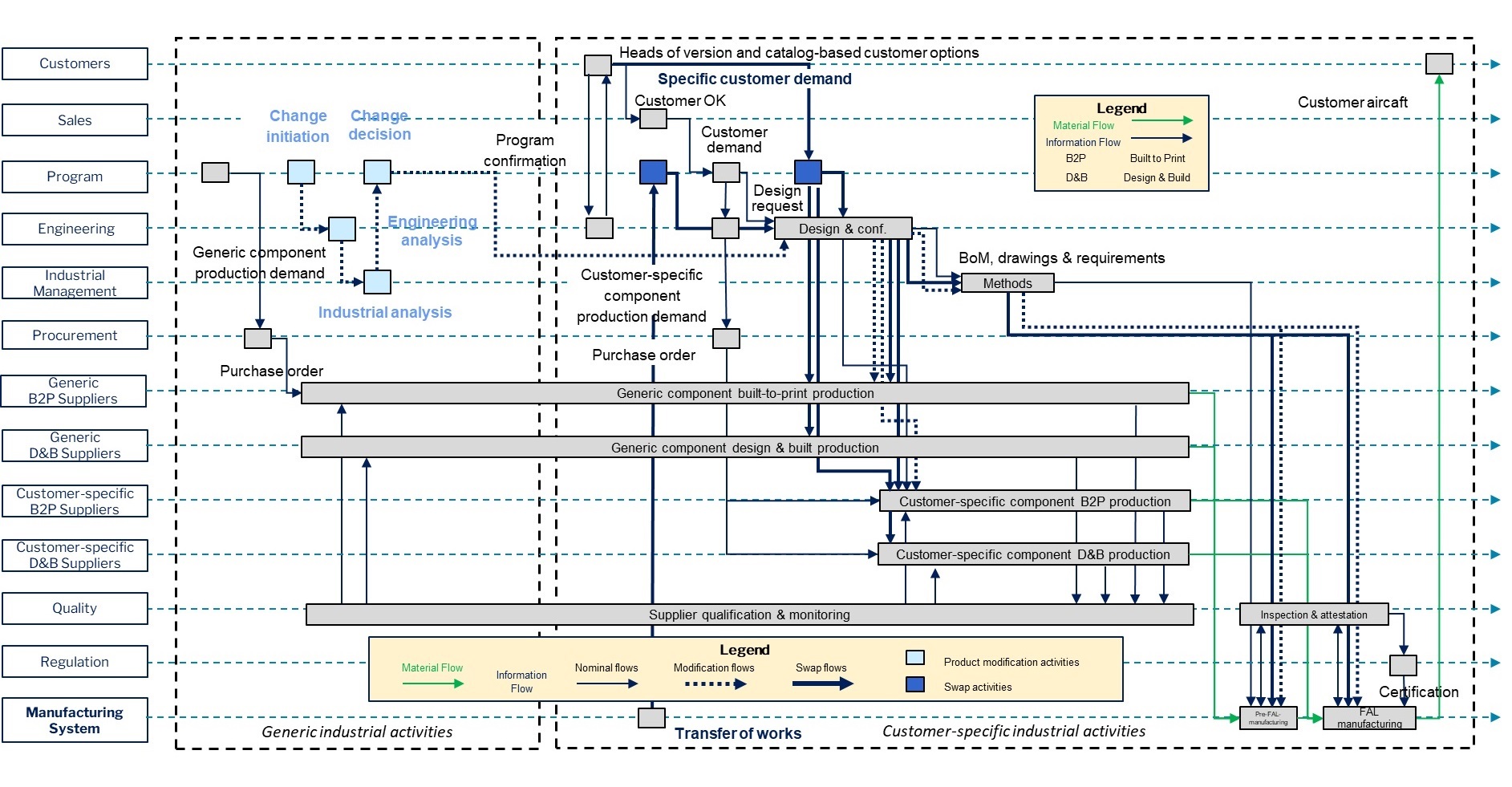

Our response was based on the construction of a system model, supporting a corresponding systemic digital twin, for the current overall / extended industrial system, consisting in the final assembly line, the involved supply chain and the industrial governance system, together with their main internal & external stakeholders such as sales, quality, engineering, procurement, customers and regulators, relying on a realistic systemic model of this global system. This allowed us to analyze the industrial system and to evaluate its main bottlenecks in relationship to the targeted industrial ramp-up, leading to relevant and significant recommendations for industrial improvement.

The outcomes

FEATURES

Service features that were deployed in this case:

– Structural & behavioral modeling of the overall / extended aircraft industrial system

– Analysis of operational data of the overall / extended aircraft industrial system

Product features that were used in this case:

– Development of a systemic model in Σ™

– Step-by-step and stochastic simulation

– Scenario simulation and evaluation

ADVANTAGES

Market trends were captured to model the evolution of customer demand as one of the core inputs of any aircraft industrial system.

The main business & industrial hazards & perturbations (e.g. change of design of an aircraft or evolution of customer needs during development, reranking of production, supplier issues, part shortages, etc.) that the overall aircraft industrial system has to deal withn were integrated in our system model.

Systemic digital twin maintenance & evolution could be regularly achieved with a very low effort

BENEFITS

Benefit #1: the very first benefit of our approach mentioned by our client was the construction of a shared global & transversal vision of its overall / extended industrial system which was currently lacking.

Benefit #2: our approach made it possible to identify the main bottlenecks of the existing global / extended aircraft industrial system in relation to the targeted ramp-up and to define improvement recommendations to move towards this target.